Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

Engineering machine shops play a pivotal role in turning complex ideas into functional, high-precision components,as the backbone for countless sectors, including aerospace, automotive, medical devices, energy, and more. While traditional machine shops were limited to basic milling and turning, modern engineering machine shops have significantly expanded their capabilities to meet the demands of high-tech and custom manufacturing projects.

This article explores five key services offered by a modern engineering machine shop, showcasing how these capabilities support innovation, reduce time-to-market, and improve product performance across various industries.

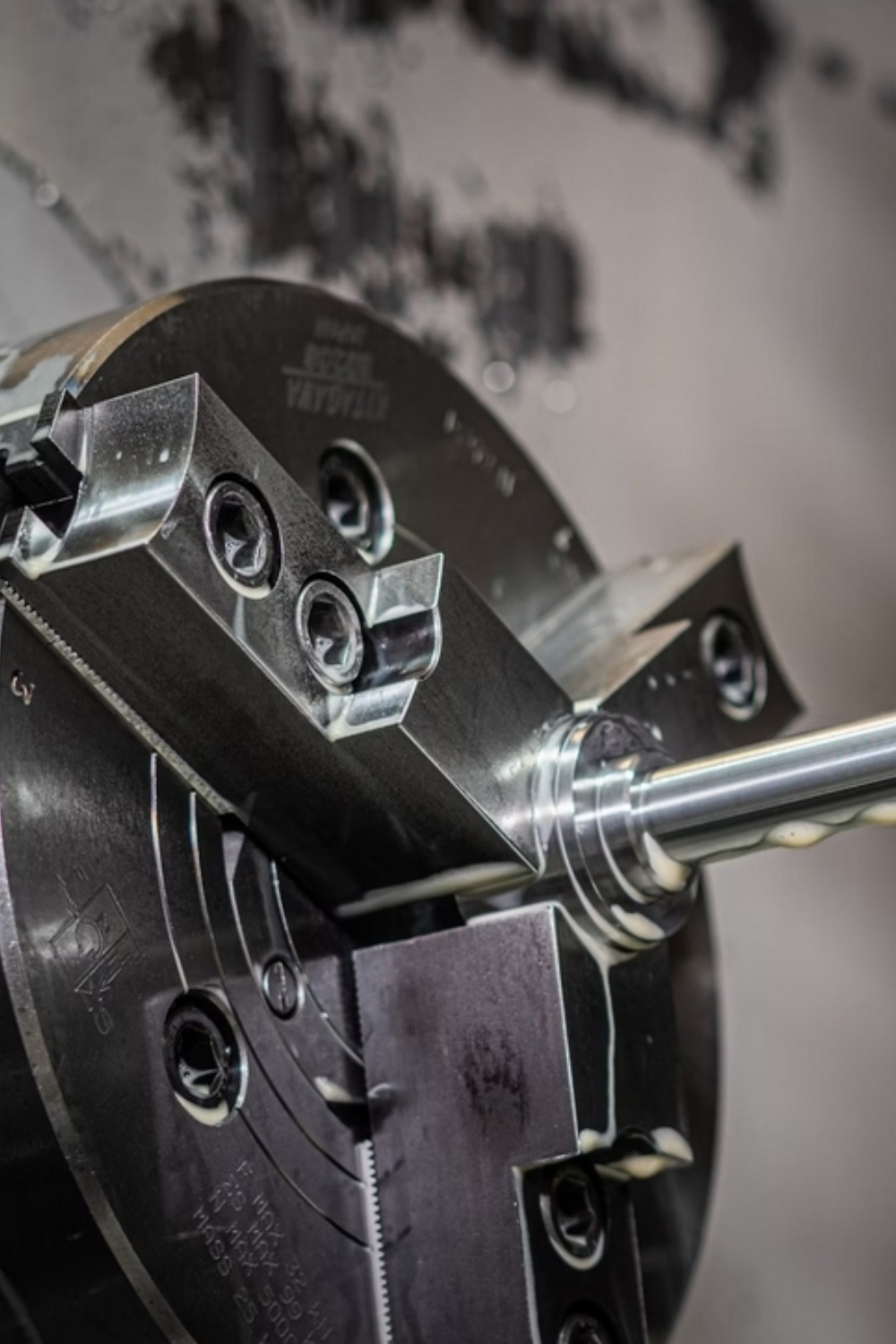

1. CNC Machining (3, 4, and 5-Axis)

Computer Numerical Control (CNC) machining is the cornerstone of any advanced engineering machine shop. Today's facilities boast a range of CNC equipment—from 3-axis vertical machining centers to sophisticated 5-axis machines capable of handling intricate geometries.

Why it matters:

CNC machining allows for the creation of parts with extremely tight tolerances and consistent quality. With programmable controls, shops can produce both prototypes and high-volume production runs efficiently. 5-axis machining, in particular, enables complex contours and undercuts to be machined in a single setup, minimizing errors and speeding up production.

Common applications:

Aerospace turbine components

Medical implants

Automotive engine parts

Precision tools and fixtures

2. Precision Grinding and Surface Finishing

Another vital service offered is precision grinding, including surface grinding, cylindrical grinding, and centerless grinding. These techniques are essential when parts require smooth surface finishes and exact dimensional tolerances that go beyond what CNC machining alone can achieve.

Why it matters:

In industries like medical, aerospace, and electronics, even minor surface imperfections can affect performance, durability, or compliance with regulatory standards. High-precision grinding ensures components not only meet design specs but also function reliably in demanding environments.

Common applications:

Hydraulic shafts and spindles

Bearing components

Gears and transmission parts

Wear-resistant machine parts

3. Prototyping and Custom Part Fabrication

Modern engineering machine shops don't just produce parts—they help engineers and designers bring ideas to life. With access to CAD/CAM software and experienced machinists, these shops are well-equipped to offer rapid prototyping services that support R&D teams during product development.

Why it matters:

Rapid prototyping accelerates design validation and iteration, reducing time-to-market for new products. Shops can work with a variety of materials including aluminum, steel, titanium, and even plastics to produce functional prototypes that behave like final products.

Common applications:

Proof-of-concept parts

Custom fixtures and jigs

One-off parts for low-volume production

Reverse-engineered components

4. Welding, Fabrication, and Assembly

Many modern engineering machine shops provide in-house welding, fabrication, and mechanical assembly to deliver fully functional assemblies rather than just standalone parts. This vertical integration ensures that all stages of production are handled by one team, reducing costs and communication errors.

Why it matters:

Customers benefit from a streamlined supply chain and faster project turnaround when welding and assembly are done in-house. Fabrication services allow shops to bend, cut, and assemble structural components, while precision welding ensures durable joins in critical applications.

Common applications:

Machine frames and housings

Custom brackets and supports

Fabricated structural components

Mechanical assemblies and subassemblies

5. Quality Control and Inspection Services

Precision means nothing without quality assurance. Top-tier engineering machine shops invest heavily in inspection equipment and processes to ensure every part that leaves the facility meets exacting standards. Tools such as Coordinate Measuring Machines (CMM), laser scanners, and optical comparators are commonly used.

Why it matters:

Quality control isn't just about compliance—it's about protecting brand reputation, reducing rework, and ensuring customer satisfaction. Detailed inspection reports and certifications are especially critical for aerospace, defense, and medical industries, where traceability and documentation are required.

Common applications:

First article inspection (FAI)

Dimensional verification

Non-destructive testing (NDT)

Process control documentation

A modern engineering machine shop is far more than a place that cuts metal. It's a high-tech facility that offers a suite of specialized services designed to support the most demanding manufacturing challenges. By leveraging cutting-edge machinery, skilled technicians, and advanced software, these shops provide comprehensive solutions that span from concept to finished product.

Whether you need a custom prototype, a precision-ground component, or a fully assembled mechanical system, partnering with a capable engineering machine shop can dramatically improve product quality, reduce lead times, and enhance your competitive edge.

As industries continue to demand higher levels of accuracy, durability, and customization, the role of the engineering machine shop will only grow in importance. Understanding the key services they offer is the first step in choosing the right partner for your next project.

About AJL Machining:

AJL Machining is a professional and industry-leading one-stop workshop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production. Our competitive edge is our ability to ensure that all of your parts are produced according to specifications, within budget, and delivered on time to meet your evolving demands. Presently, we serve over 80% of our business to multinational corporations in China, as well as overseas customers.

To learn more, please don't hesitate to contact us via email at sales@ajlmachining.com, or visit our website at www.ajlmachining.com

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203