Inquiry

Project Review

Machining

Quality Control

Pass/Fail

Delivery

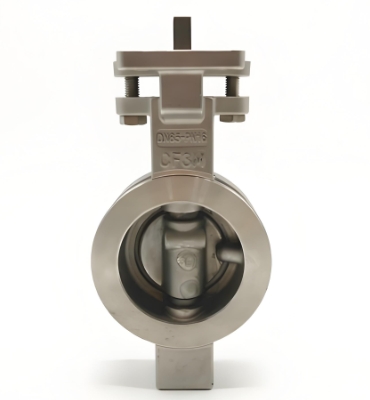

Flanged butterfly valves are widely used in pipelines for their compact design, quick operation, and excellent sealing performance. Their simple yet efficient structure makes them ideal for water treatment, HVAC, chemical, and oil & gas applications.

This blog explores their core components, including the valve body, disc, seat, and flanged connections, along with their advantages and common uses. Whether you need low flow resistance, bidirectional sealing, or cost-effective fluid control, flanged butterfly valves deliver reliable performance.

Let’s dive into their structural features and why they’re a top choice for industrial systems.

Valve Body Structure

· The valve body is typically cast or forged to ensure sufficient strength and rigidity, enabling it to withstand pipeline pressure.

· The internal cavity is designed for smooth flow, minimizing fluid resistance and turbulence, thus improving flow efficiency.

Disc (Butterfly Plate) Structure

· The disc is the core component, rotating around its axis to control fluid flow.

· It is usually circular or elliptical to reduce friction against the seat, enhancing sealing performance and lifespan.

· Material options include metal, rubber-coated, or PTFE-lined discs to suit different media (water, gas, corrosive fluids, etc.).

Seat Structure

· The seat is made of elastic materials (e.g., rubber, PTFE) to ensure tight sealing with the disc.

· Designed with flexibility to accommodate disc rotation, improving seal integrity under pressure.

Flanged Connection

· Features flanged ends for simple, leak-proof pipeline connection.

· Complies with international standards (ANSI, DIN, GB) for compatibility with various piping systems.

Actuation Methods

· Supports manual, electric, pneumatic, or hydraulic actuation for flexible operation.

· Designed for ease of use and reliability, ensuring long service life.

Additional Features

· Compact and lightweight, facilitating easy installation and maintenance.

· Hydrodynamically optimized to reduce flow resistance and noise.

· Optional anti-corrosion coatings for harsh environments (e.g., seawater, chemicals).

Key Advantages of Flanged Butterfly Valves

✔ Low flow resistance – Ideal for high-efficiency systems.

✔ Quick operation – 90° rotation enables fast shutoff/regulation.

✔ Bidirectional sealing – Suitable for varying flow directions.

✔ Cost-effective – Simple design reduces manufacturing/maintenance costs.

Common Applications

· Water treatment, HVAC, petroleum, chemical, and power industries.

· Large-diameter pipelines where compact, lightweight valves are preferred.

For high-pressure/high-temperature applications, metal-seated designs are recommended over soft-seated (rubber/PTFE) variants.

About AJL Machining:

AJL Machining is a professional and industry-leading one-stop workshop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production. Our competitive edge is our ability to ensure that all of your parts are produced according to specifications, within budget, and delivered on time to meet your evolving demands. Presently, we serve over 80% of our business to multinational corporations in China, as well as overseas customers.

To learn more, please don't hesitate to contact us via email at sales@ajlmachining.com, or visit our website at www.ajlmachining.com

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203