Inquiry

Project Review

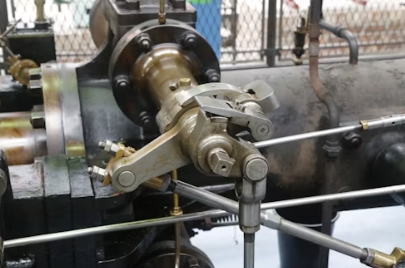

Machining

Quality Control

Pass/Fail

Delivery

In the fast-paced world of innovation and product development, speed, precision, and flexibility are critical to success. For startups and entrepreneurs aiming to bring groundbreaking ideas to life, rapid prototype machining has become an essential solution. Unlike traditional manufacturing methods, rapid prototype machining provides a streamlined, efficient way to create high-quality, functional prototypes that accelerate the product development cycle and reduce risk.

This article explores the top benefits of using rapid prototype machining for startups and innovators, and why it’s a game-changer for turning concepts into market-ready solutions.

1. Speed to Market

One of the most significant advantages of rapid prototype machining is speed. Traditional manufacturing techniques often require weeks or even months to produce prototype parts. In contrast, CNC-based rapid machining processes can deliver fully functional prototypes within days, if not hours.

Startups, especially those in competitive markets, need to move quickly to capture attention, secure funding, and validate concepts. Rapid prototype machining allows them to iterate quickly, test designs, and make adjustments without long lead times. This agility can be the difference between being first to market and missing a crucial opportunity.

2. Enhanced Product Iteration and Testing

Innovation often involves trial and error. Rapid prototype machining enables startups to develop multiple iterations of a product in a short period. These high-fidelity prototypes are not only accurate in form but also in function, allowing for real-world testing under actual conditions.

With each iteration, engineers can evaluate performance, identify design flaws, and make data-driven improvements. This results in a more refined final product, increased confidence in functionality, and ultimately, a better chance at market success.

3. High Precision and Quality

Startups can't afford to compromise on quality when presenting a prototype to investors, customers, or stakeholders. Rapid prototype machining uses advanced CNC machines that offer tight tolerances and repeatable accuracy. This ensures that each component meets exact specifications, even in early-stage development.

Unlike 3D printing or other additive processes that may lack surface finish or strength, machined prototypes can be made from actual production-grade materials, giving startups a more accurate representation of the final product.

4. Material Versatility

Rapid prototype machining supports a wide range of materials—from plastics like ABS and Delrin to metals like aluminum, stainless steel, and titanium. This flexibility allows startups to test different materials and determine which one best suits their product’s requirements in terms of strength, heat resistance, weight, or cost.

Being able to evaluate materials early on helps prevent costly redesigns later in the development process. Additionally, it enables startups to demonstrate a working model that closely mirrors the final product, making it more appealing to potential investors or buyers.

5. Cost-Effective Development

For startups operating on limited budgets, every dollar counts. While rapid prototype machining may have a higher per-unit cost compared to mass production, it is far more cost-effective than traditional prototyping methods when it comes to short-run parts or single units.

By avoiding the need for expensive tooling, dies, or molds, startups can significantly reduce initial capital investment. This allows more resources to be allocated to product development, marketing, or other critical business areas.

6. Improved Investor and Stakeholder Confidence

Investors want to see more than a concept—they want proof that a product is feasible and manufacturable. A high-quality prototype produced through rapid machining communicates professionalism, technical competence, and serious commitment to product development.

Being able to showcase a functional, physically representative prototype can greatly enhance presentations, strengthen pitches, and increase the likelihood of funding. It demonstrates not only vision but execution—two critical factors in startup success.

7. Seamless Transition to Production

Another key benefit of using rapid prototype machining is the ease of transitioning from prototype to full-scale manufacturing. Because the same CAD files used for prototyping can be adapted for production, there’s less chance of design errors or miscommunication between development and manufacturing teams.

This compatibility also shortens the development timeline and reduces rework, leading to faster commercialization and lower overall production costs.

8. Customization and Design Freedom

Startups often operate in niche markets or target highly specialized needs. Rapid prototype machining provides the flexibility to explore customized solutions without being constrained by tooling limitations. Design changes can be implemented quickly, and prototypes can be tailored for specific user feedback or testing environments.

This design freedom is particularly valuable in sectors like medical devices, aerospace components, or consumer electronics, where innovation and precision are paramount.

9. Reduced Risk of Failure

Developing a product without proper testing or validation introduces significant risk. By using rapid prototype machining, startups can identify and address potential flaws before they become costly issues in mass production. These early-stage insights help mitigate design errors, avoid manufacturing problems, and reduce warranty or recall concerns down the line.

Ultimately, this leads to a more robust product and a stronger brand reputation—both essential for long-term success.

10. Supports Lean Startup Methodologies

Rapid prototype machining aligns perfectly with lean startup principles, which emphasize building minimal viable products (MVPs), gathering feedback, and iterating quickly. By producing functional, testable prototypes with minimal waste and investment, startups can adapt to market feedback in real time.

This iterative, agile development cycle reduces guesswork, encourages innovation, and increases the likelihood of delivering a product that truly meets customer needs.

Rapid prototype machining is more than just a manufacturing technique—it’s a strategic asset for startups and innovators who need to move fast, think creatively, and deliver high-quality products. From accelerating time to market and enabling design iteration to improving product quality and investor confidence, the advantages are substantial.

In today’s dynamic business environment, where innovation is the lifeblood of progress, having access to reliable, high-precision, and flexible machining solutions can empower startups to compete with established players and bring visionary ideas to life.

Whether you're launching a new hardware product, refining a breakthrough concept, or looking to secure funding with a tangible prototype, rapid prototype machining is an indispensable tool on the journey from idea to reality.

About AJL Machining:

AJL Machining is a professional and industry-leading one-stop workshop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production. Our competitive edge is our ability to ensure that all of your parts are produced according to specifications, within budget, and delivered on time to meet your evolving demands. Presently, we serve over 80% of our business to multinational corporations in China, as well as overseas customers.

To learn more, please don't hesitate to contact us via email at sales@ajlmachining.com, or visit our website at www.ajlmachining.com

AJL Machining is a professional and industry-leading one-stop shop for custom metal parts services. We have our own factory and a reliable network of partners that enable us to cater to your requirements ranging from prototypes to large-scale production.

Add: No 58, Chenghu Road, Kunshan, Suzhou City, Jiangsu Province, China 215333

Email:sales@ajlmachining.com

Tel: +8613522650203